|

OPEN-ROOF GREENHOUSE PROJECT PICTURES

Construction 1-10 11-20 21-30 31-40 41-50 Crop Production 51-60 |

|

|

First, the concrete was poured along the perimeter of the entire greenhouse in those areas that would later serve as sidewalks. |

|

Close-up of one of the heating lines embedded into the newly installed concrete floor. |

|

Concrete was just poured in one of the sidewalk. A plastic covering is used to keep rain off the drying concrete. |

|

The main greenhouse floor was poured in two sections. This picture shows the situation just before the concrete truck arrived. |

|

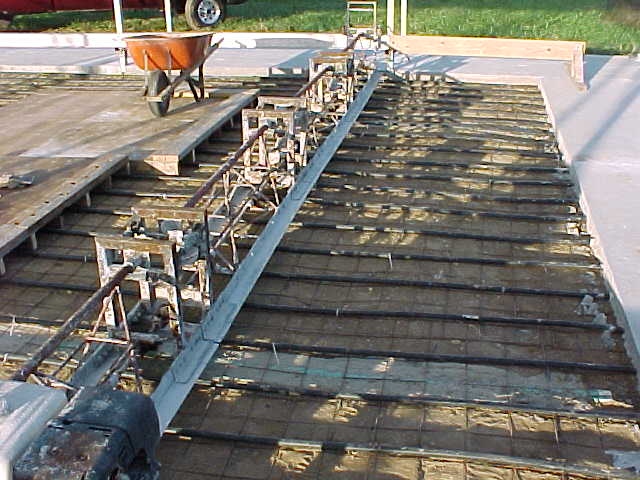

A motorized power screed is used to make a "W"-shaped profile in the top of the concrete floor. The power screed is supported by beams that were temporarily attached to the greenhouse posts. |

|

The first wheelbarrow of concrete is dumped in position. A motorized screed is visible in the front of the picture. This screed will be pushed over the wet concrete to make a "W"-shaped profile in the top of the concrete floor. The lower areas of the floor are positioned directly above the (green) nutrient solution distribution pipes. |

|

A motorized power screed is used to make a "W"-shaped profile in the top of the concrete floor. This "W" shape will help quickly drain the water from the floor after each irrigation cycle. |

|

The concrete truck is ready to dump more concrete on the floor area. |

|

Wheelbarrows are used to bring concrete to the desired location. A temporary and moveable wooden support is used to prevent any damage to the polypropylene heating lines. |

|

A rotating power trowel is used when the concrete is just hard enough to walk on. This trowel does the final smoothing of the top of the concrete floor. |