|

HEADHOUSE CONSTRUCTION

|

|

Installation of

wood trusses to support the roof of the headhouse. |

|

Two-inch thick

perimeter insulation (approximately 2 feet deep) is installed along the

outside walls of the headhouse. This perimeter insulation makes for an

effective heat-loss barrier.

|

|

Framing of the

interior walls for the cold storage room located in the headhouse. Note

the yellow fiberglass insulation blankets in the outside walls and the

metal clad ceiling. Fiberglass insulation blankets were installed in the

attic, just above the metal ceiling panels.

|

|

Inside the headhouse

(40 feet wide by 96 feet long), a utility room is constructed. Because the

boilers would be installed inside this room, the local building code

required this room to have a high fire rating. Therefore, the walls of the

utility room were constructed from concrete blocks.

|

|

Two natural gas fired

hot-water boilers (1.2 MBtu/hr input each) were installed in the utility

room.

|

|

General view of the

plant growth room inside the headhouse. |

|

The office area with

the environment control computer system. |

|

The finished cold

storage room, large enough to hold several days of harvested product. |

|

The main work area

inside the headhouse is under construction. The greenhouse is located to the

left of this picture. |

|

The washing station

inside the headhouse is used for cleaning the Styrofoam™ floaters. A weak

bleach solution is applied before the floaters are thoroughly rinsed.

|

|

The main entrance

door to the facility (facing East) and, to its right, a loading dock with

overhead door. |

|

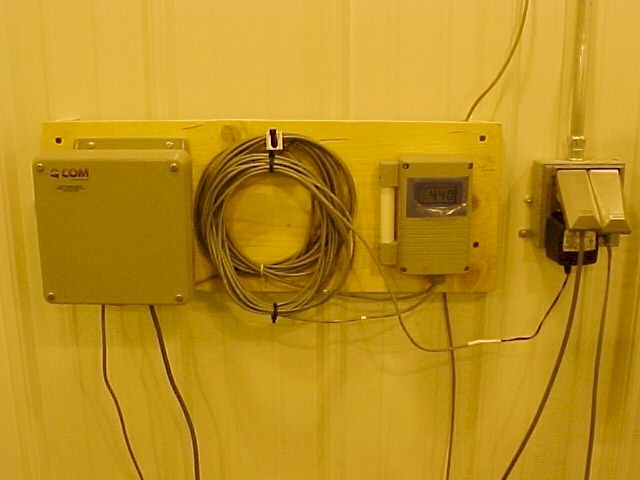

The utilities

(electric, gas, water, and phone) were brought into the building from the

West wall of the headhouse. Note the weather station (wind direction, wind

speed, outside temperature and humidity, and solar radiation) at the ridge

of the headhouse. |

|

A (liquid) carbon

dioxide tank with refrigeration unit (to the right) is installed along the

North wall of the headhouse. The liquid carbon dioxide is vaporized before

it is directed to the greenhouse and growth room. Carbon dioxide enrichment

is used to increase crop growth. |

|

Liquid oxygen tanks

are supplying vaporized oxygen gas to the recirculation nutrient solutions

in each of the four ponds. An automatic switching valve (center) is needed

to switch from one tank to the other when the first tank runs empty.

|

|

Custom-made,

water-cooled high-pressure sodium lamp bulb (600-watt). Water is pumped

through the outer glass envelope. The operating lamp heats the cooling water

as it passes through the bulb. Note the inlet and outlet ports to the sides

of the lamp bulb. |

|

Top-view of the

installation of a water-cooled high-pressure sodium lamp and reflector

located in the growth room. The lamp and reflector are mounted in a two by

two feet ceiling panel, which is part of a so-called false ceiling. Note the

black hoses bringing cooling water to and from the lamps. The (heavy)

luminaire ballast is located several feet away from the lamps and is not

supported by the false ceiling. |

|

Operating water

cooled lamp |

|

Bottom-view of the

installation of a water-cooled high-pressure sodium lamp and reflector in

one of the ceiling panels located in the growth room.

|

|

A recirculating

chiller removes heat from the cooling water and returns it to the

water-cooled high-pressure sodium lamps located in the growth room.

|

|

A carbon dioxide

sensor inside the growth room registers the carbon dioxide concentration.

The sensor communicates with the environment control system and the computer

operates a solenoid valve in the carbon dioxide supply line. A similar setup

is used in the greenhouse to control its carbon dioxide concentration.

|

|

Back

to FH Greenhouse |